How does the material selection and design of this Unshielded Tool-Less Module ensure its stability and reliability under different environmental conditions?

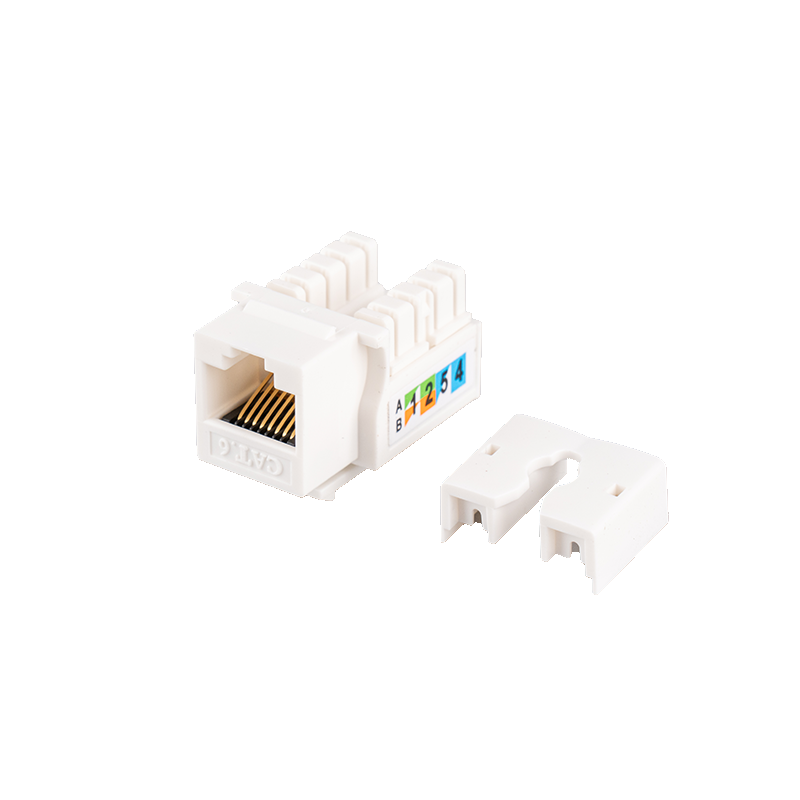

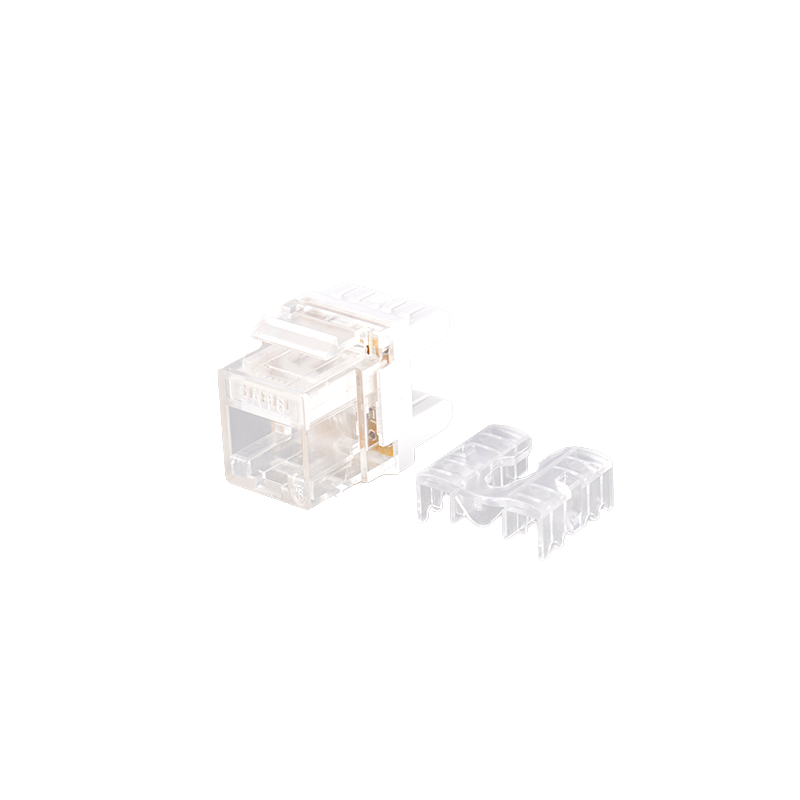

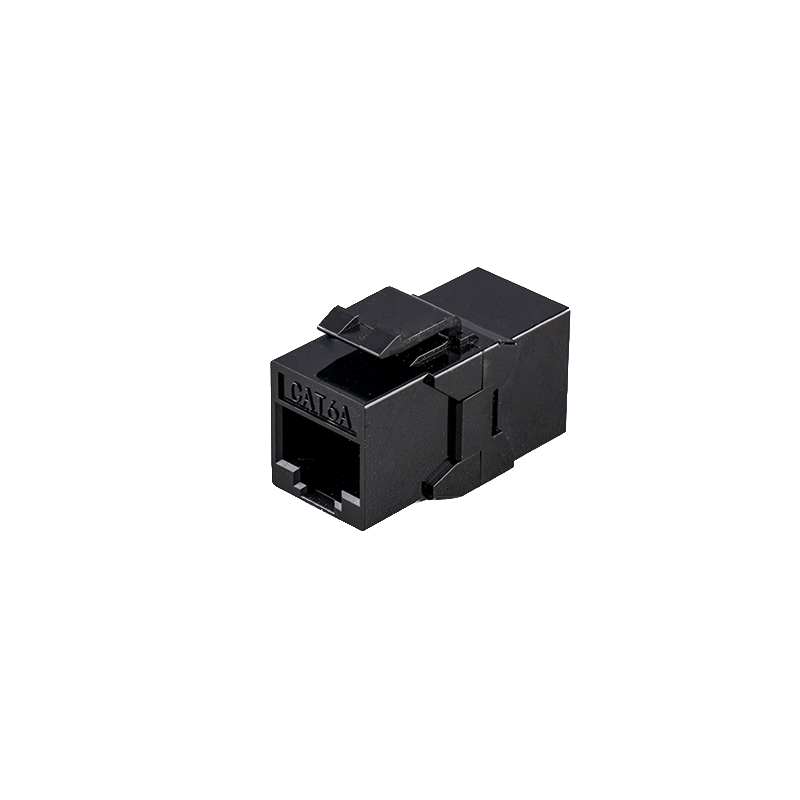

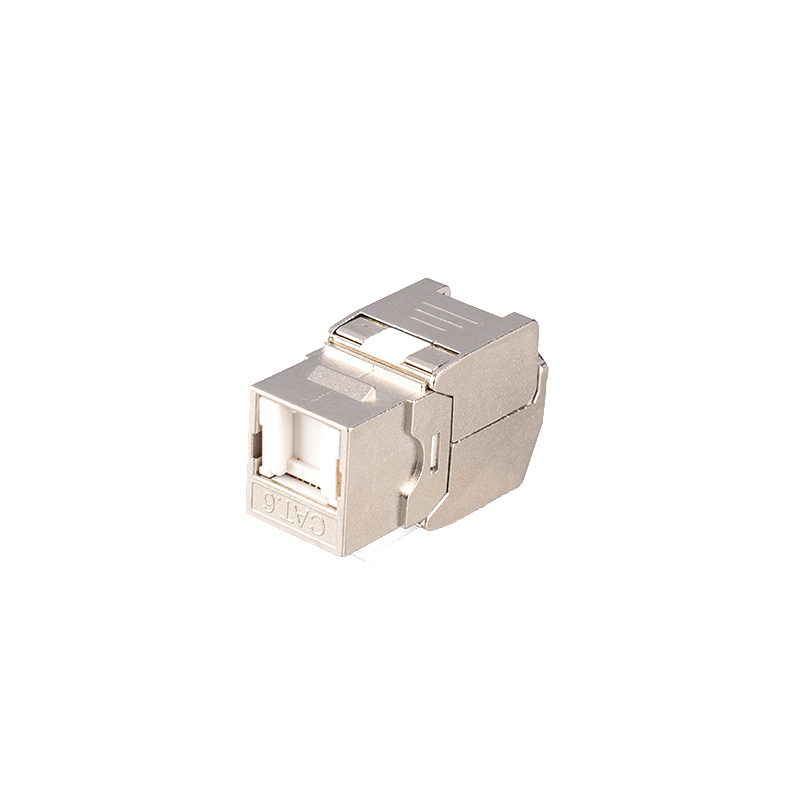

The PC material of the Unshielded Tool-Less Module not only has basic flame retardancy, but also further improves its flame retardancy level through the addition of special additives, which can delay the spread of fire under extreme fire conditions and buy precious time for personnel evacuation and fire source control. During the production process, the material must undergo rigorous weathering tests, including simulation experiments such as high temperature aging, low temperature shock, and humidity cycling to ensure that stable physical and chemical properties can be maintained under various climatic conditions. The selected PC material must also meet environmental protection standards, such as halogen-free and low smoke requirements, to reduce the impact on the environment and potential health risks.

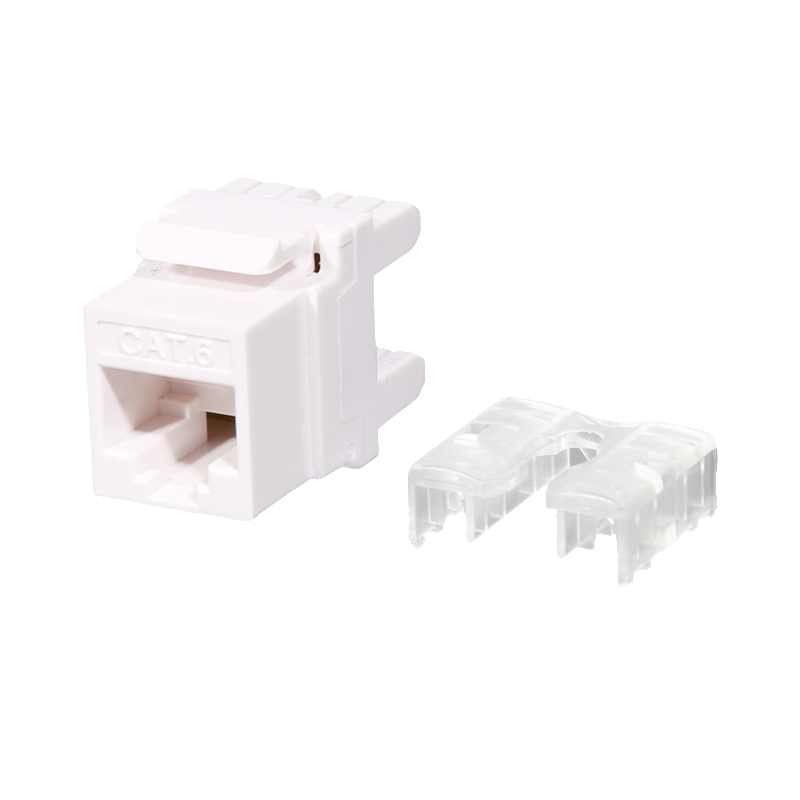

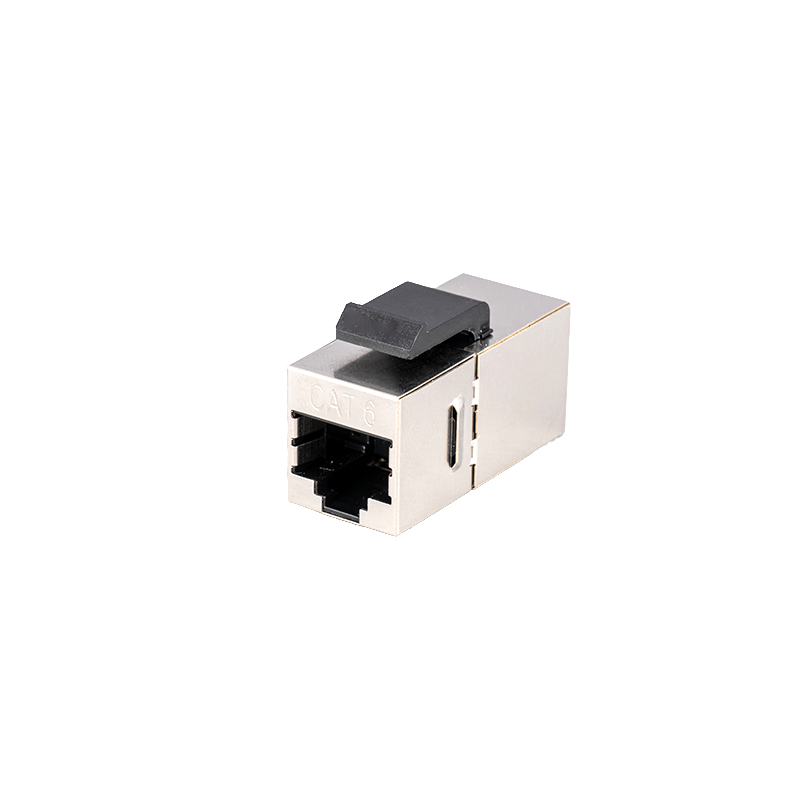

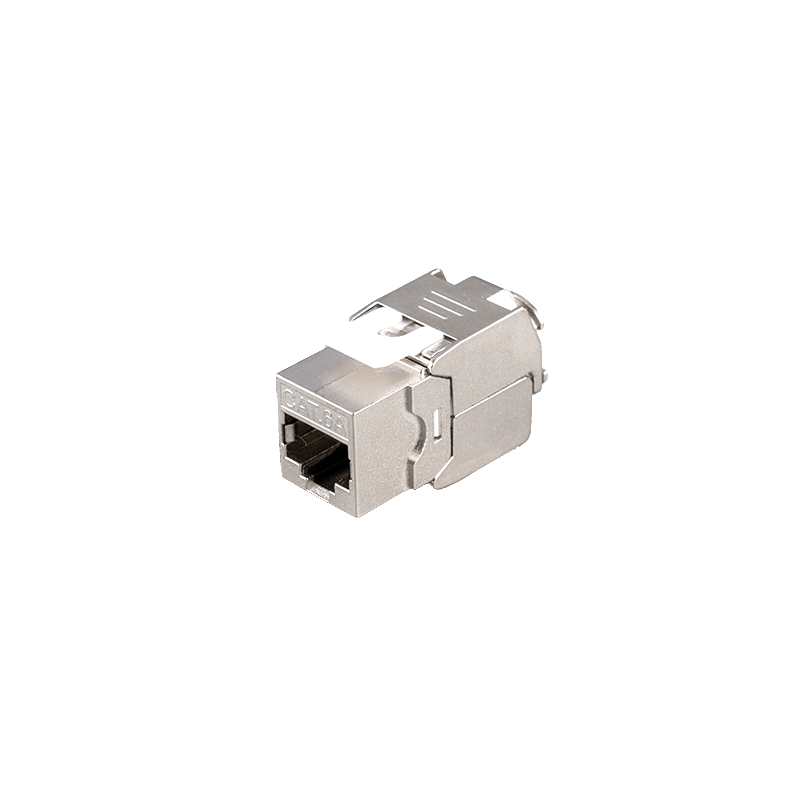

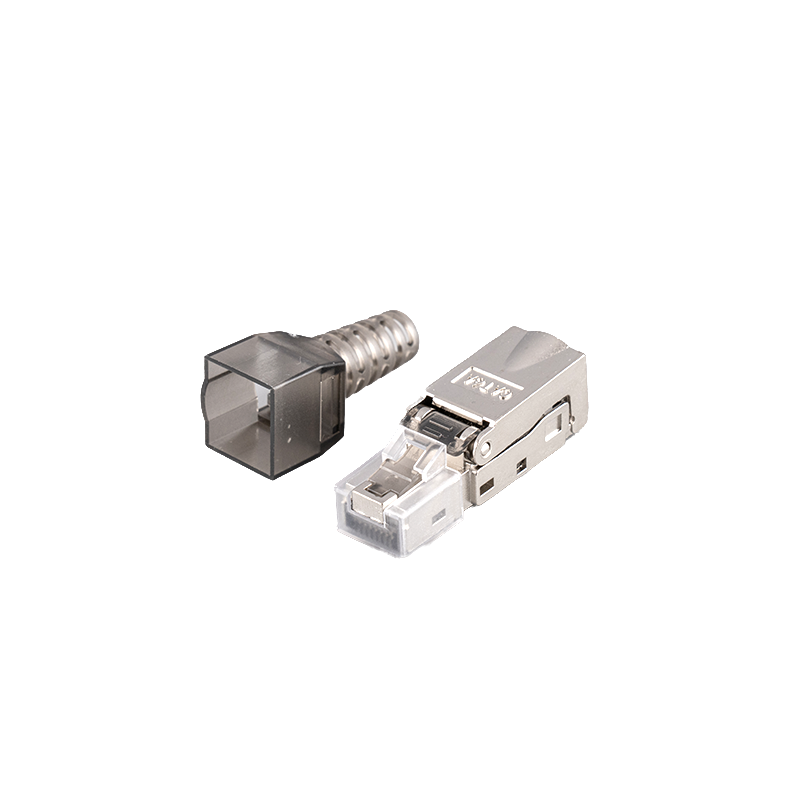

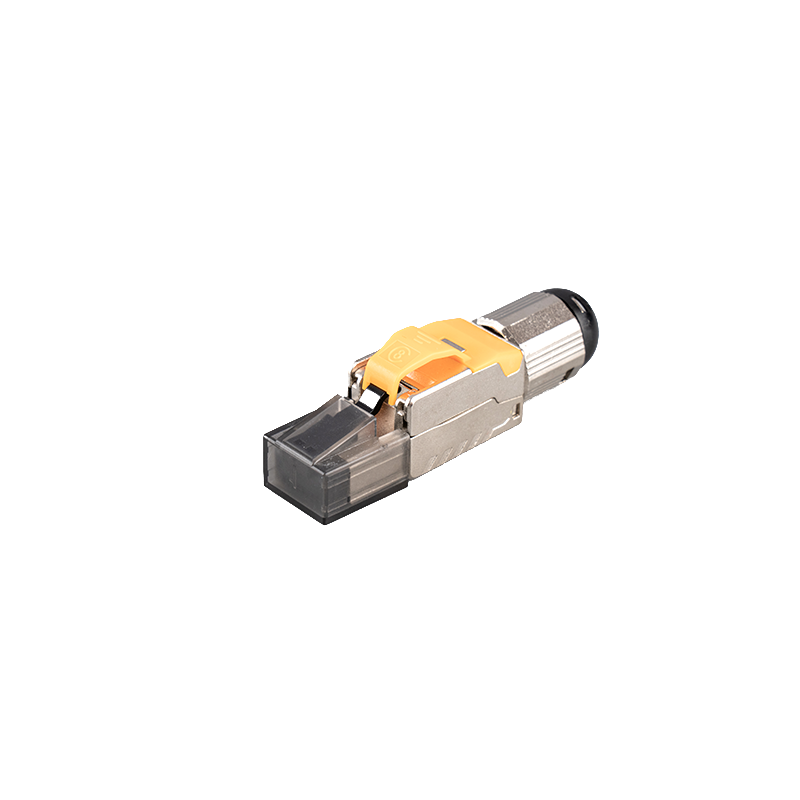

As the material of the IDC wire post clamp, the alloy composition of phosphor bronze is carefully formulated to achieve optimal conductivity, corrosion resistance and elasticity. This optimization ensures that stable electrical and mechanical properties can be maintained even in harsh environments. In order to further improve the corrosion resistance and wear resistance of phosphor bronze IDC wire post clamps, surface treatment processes such as gold plating and nickel plating are usually performed. These treatments not only enhance the corrosion resistance of the material, but also improve the conductivity of the contact surface and reduce wear during the plugging and unplugging process.

The 45-degree angle design not only improves the geometry of the contact point, but also improves the stability and reliability of the contact by optimizing the distribution of contact force. This design reduces the loose contact caused by cable vibration or temperature changes. The design also has a certain cable guiding function, which can guide the cable to enter the module at the correct angle and direction, reducing the performance degradation caused by cable twisting or bending.

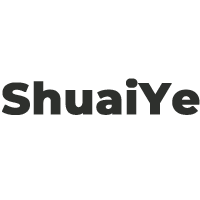

The snap-on design usually includes a double locking mechanism, that is, it can be locked again through additional actions after the initial snap-on. This design greatly enhances the fixing effect of the protective cap and prevents it from falling off due to accidental collision or vibration. A sealing design is usually adopted between the protective cap and the module body to prevent impurities such as dust and moisture from entering the module. This sealing performance is particularly important in humid or dusty environments.

This unshielded tool-free module combines selected materials and unique design to build a sturdy and reliable connection system. It can not only withstand the challenges of various environmental conditions, but also maintain stable performance in long-term use. In addition, the tool-free design not only improves the efficiency of installation and maintenance, but also reduces the risk of performance problems caused by human factors. Therefore, this module has broad application prospects in communications, data centers, industrial automation and other fields.

英语

英语 中文简体

中文简体