Does excessive force when plugging and unplugging modular plugs cause the socket to deform?

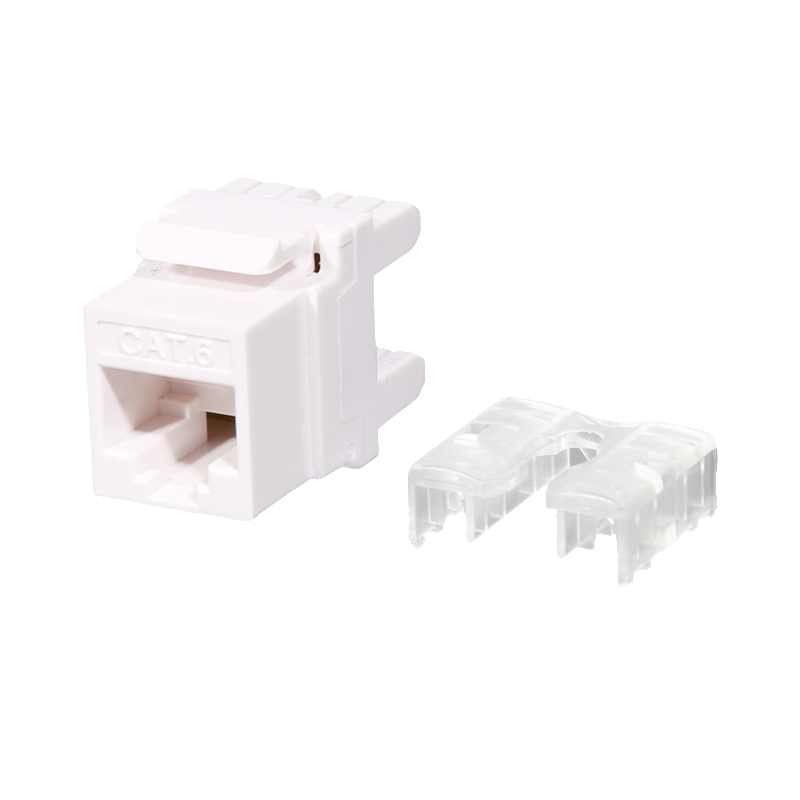

Using excessive force when plugging or unplugging modular plugs can indeed cause the socket to deform, especially if the operation is done at an incorrect angle or in an improper manner. The socket is typically composed of a plastic casing and internal metal contacts, designed to withstand normal plug-in operations. However, excessive force or frequent rough handling can affect the structural integrity of the socket.

First, the plastic parts of the socket are relatively fragile. Although they are sturdy enough for regular use, if too much force is applied during plugging or unplugging, the plastic casing may deform due to uneven pressure. This is particularly common when unplugging without first pressing the clip on the plug to release the lock mechanism in the socket. If force is applied without releasing the lock, the slot inside the socket may be compressed and deformed. This deformation can prevent the plug from locking securely into place when reinserted, causing the plug to loosen, which can affect the stability of the network connection and result in frequent disconnections or loose connections.

Additionally, the internal metal contacts of the socket are also susceptible to damage. These contacts interact with the copper pins on the plug to transmit signals. When excessive force is used during plugging or unplugging, the contacts may become compressed or even bend or shift. If the contacts fail to make proper contact with the copper pins of the plug, the transmission of network signals will be disrupted, leading to an unstable or completely failed connection. If the contacts are severely bent, signal loss, increased latency, or interrupted data transmission may occur.

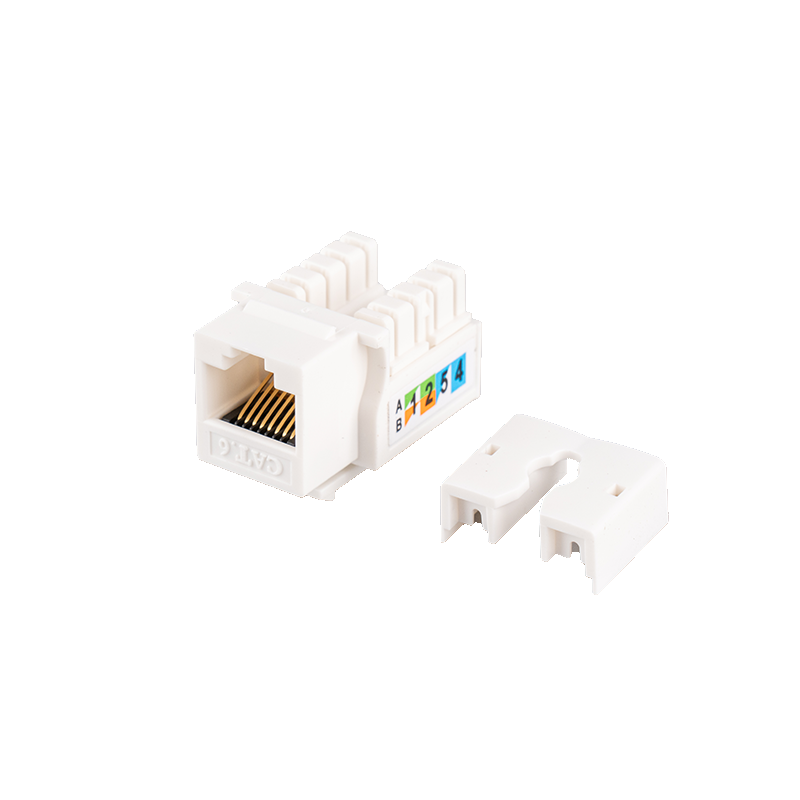

Moreover, frequent and forceful plugging and unplugging will accelerate the overall wear and tear of the socket, causing the internal structure to loosen. When the socket is subjected to continuous excessive force, the internal plastic slots and metal contacts may gradually become dislodged. The plug will no longer fit securely into the socket, making it more likely to loosen and impair the stability of the network. Once the socket is loose, even minor vibrations or movements can cause the plug to fall out, further worsening the connection issues.

In more severe cases, the deformation of the socket may not be limited to its exterior. Since the socket is often soldered to the device’s motherboard or circuit board, excessive force during plugging or unplugging, especially at an incorrect angle, can exert pressure on the device's internal solder points. The solder points may break, causing the entire network port to malfunction and making any network connection impossible. In such instances, repairing the socket or replacing the device can be costly.

In summary, excessive force when plugging and unplugging modular plugs can lead to deformation of the socket’s plastic casing, damage to the metal contacts, and even affect the device’s internal circuits. Therefore, it is important to apply appropriate force and avoid unnecessary rough handling to extend the lifespan of the equipment and maintain a stable network connection.

英语

英语 中文简体

中文简体